Menu

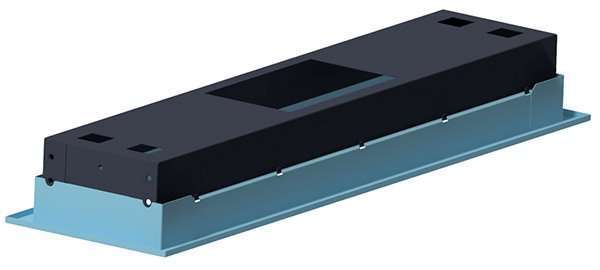

RECESSED CEILING HEATER MOUNT

Britannia’s client had an issue with a low-value accessory of their main product. The sheer size of the part made shipping expensive, especially when compared to the price of the part – Its size and cost when shipped throughout Australia and internationally was just not sustainable. Britannia offered to assist with the specific aims of minimising the package volume, maintaining the product strength and design integrity whilst maintaining cost competitiveness.

THE BRIEF

Reduce the volume when packed without compromising the function

No increase in overall manufacture costs (decrease preferred)

Improve installation process for quick and easy assembly

RE:ENGINEERED

Britannia’s design team identified the design items below that could be exploited:

The current design was made in two parts with a large base and a small frame surround. The SS frame did not use material efficiently.

There are five components making up the steel backing box, if this could be incorporated into one metal blank sheet folded on Britannia’s Salvagnini panel folder potential savings could be achieved

The current design is made from 1.0mm material, if the Salvagnini folder could be used, the material thickness may be able to be lowered with an increase in the number of folds used while on the machine.

The base was powder coated, but only the external face is visible. Suggestion to change material to COLORBOND®.

the result

By extending the fascia and allowing it to telescope from the base only when installed enabled the unit to be packed in a collapsed state.

The use of the Salvagnini and COLORBOND® as the base material reduced the thickness requirement of the unit and the need for powder coating.

This allowed all critical design items to be achieved:

Telescoping reduced shipping volume by 50%

Extra folding increased strength whilst reducing material cost

Lighter and cheaper product that was safer to handle

Collapsed packing form required less packing material due to improved rigidity

Powder coating was replaced with COLORBOND® materials

The redesigned base allowed a redesign of the mounting brackets which Improved the installation process

Overall price reduction